Coffee Drying

Vegetable Growing

"Bunk Beds"

We are so excited that you have taken an interest in our

Innovative Bunk Bed Drying Tables!

A - Natural Coffee being sundried on top of table during coffee drying season.

B - Shade Cloth or Agricultural Cloth. There is an option for variation with this material. Material used should be resistant to UV decay, sufficiently closed to keep coffee from falling through any holes/openings, and sufficiently open to allow air to come through the material to dry the coffee from below. The cloth should not be fastened down, useful when compiling the coffee for night rest and for collection when dry.

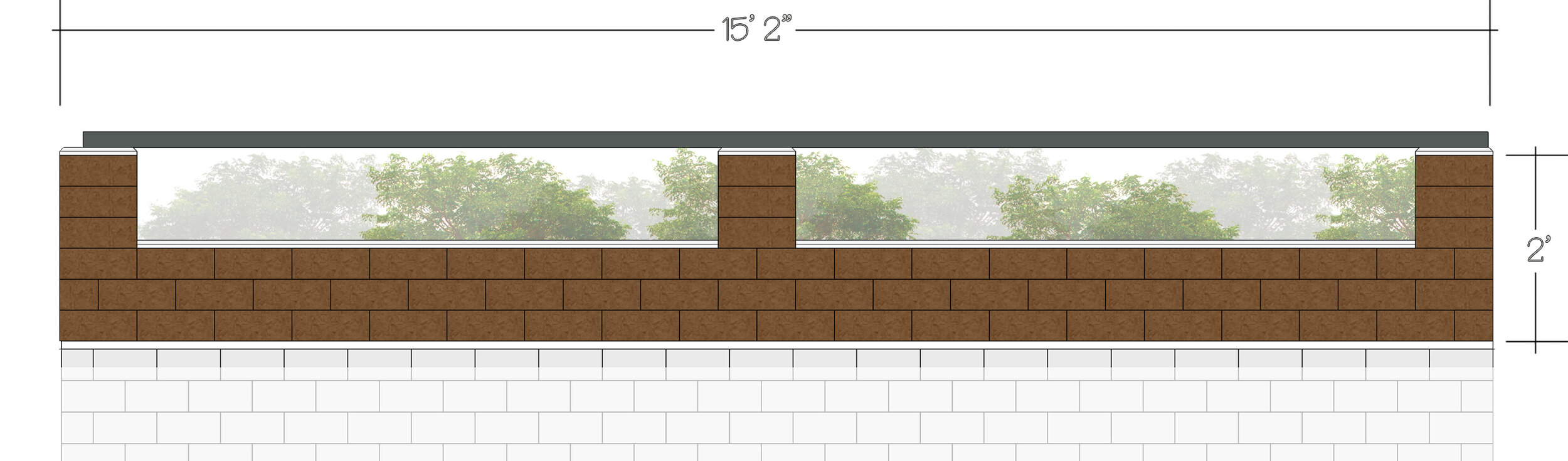

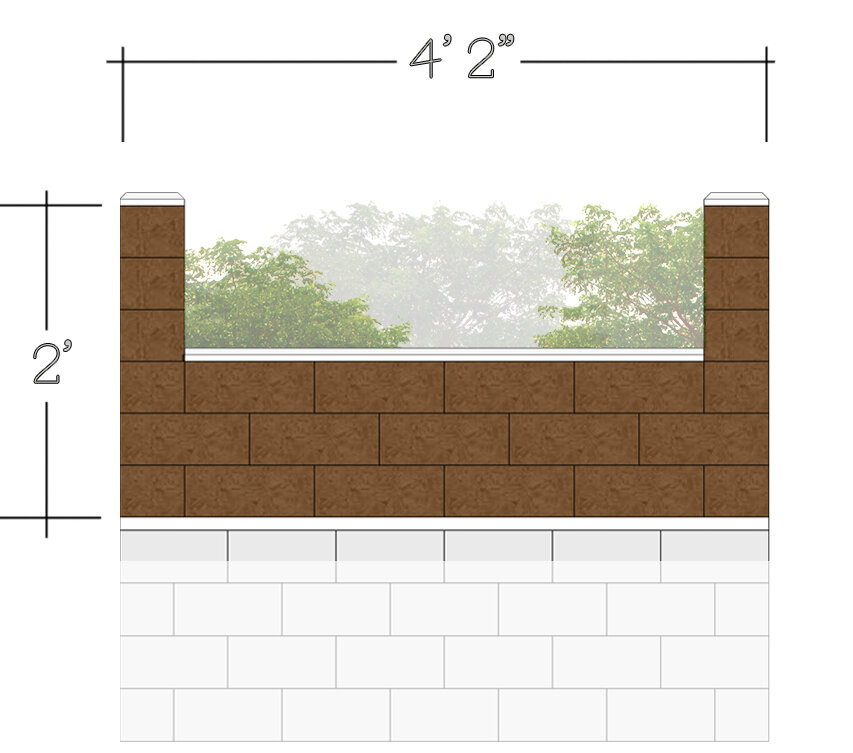

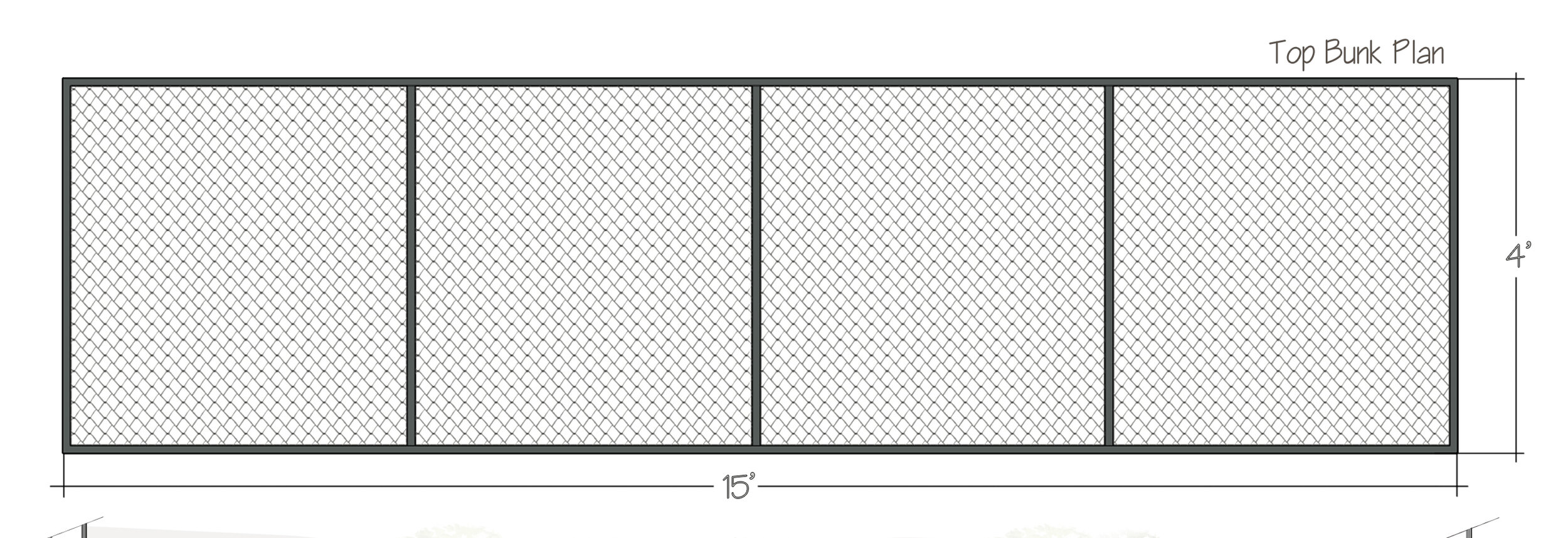

C - Metal Table Top. Constructed out of 1x2” metal hollow tubing. 1” screen mesh welded to frame. Sizes and types of materials for this frame could vary from place to place based on availability and on the size of the beds to be constructed. Attention should be given to use materials and sizes sufficient to create a rigid frame. The frame should not bend and deflect when loaded with wet coffee. Porous metal table rests on six legs extending up from bottom bunk bed. See page 01 for more information.

D - Waterproof Tarp. Plastic or any water repelling material may be used. The material should not be transparent. Tarp hangs during the day along the side of the bed, then wraps and covers coffee during night rest and rainy conditions. We were able to use a black parachute-type material that is both waterproof and tear-proof.

E - BTL “Bunk Bed.” Concrete block below grade, compressed earth block above.

What to Expect When Building

Cost Estimate for Replication: 130 Euro for one complete “bunk bed” set

Experts and Consultants needed for replication: Mason, Welder, Coffee Processing Specialist and Natural Farming Consultant.

Time to Build/implement: one mason can build one bottom bunk in one day and one welder can build two top bunks in one day

Materials Needed per Bed: 152 Interlocking Compressed Earth Blocks, 12 linear feet of rebar divided into 6, 2’ sections, 1.5 bags of cement, Cinderblock for below grade foundation (as needed according to site or) average of 40 blocks per foundation.

Staffing for innovation: During harvest, BTL hired one lady to manage 10 tables each. The ladies all work together to wash the cherries and process and dry on raised beds and check moisture and store in bags. So, for 300 tables, 30 ladies are required for maintaining quality and keeping lots separate.

Equipment: The surface of the top bunk drying bed is made from rectangular metal tubing welded together for the frame with a wire screen as the surface for the bed. In addition, a mesh bed sheet is placed on top and a durable rainproof covering is attached on the side that is easily pulled off and back over the coffee to protect from dew and rain. When the season is over, the metal table surfaces are lifted off of the garden beds and stacked together under a shelter. The table surfaces are durable, lightweight, and stackable in the off-season. The surface size for one bed is 48x180x2in The bottom bunk is constructed with cement and cinderblock for the foundation, Interlocking Compressed Earth Blocks (ICEB) for walls, and six bed posts to support the top bunk bed frame. The ICEB have holes so that iron rods can be cemented in for support.

Additional Note: The garden bed mixture is made up of cow manure, composted banana trees, coffee pulp/hulls, rice husk biochar with the added help of red wiggler worms to make rich, organic garden soil and indigenous microorganisms (IMO) to compliment the living soil.

Construction Instructions

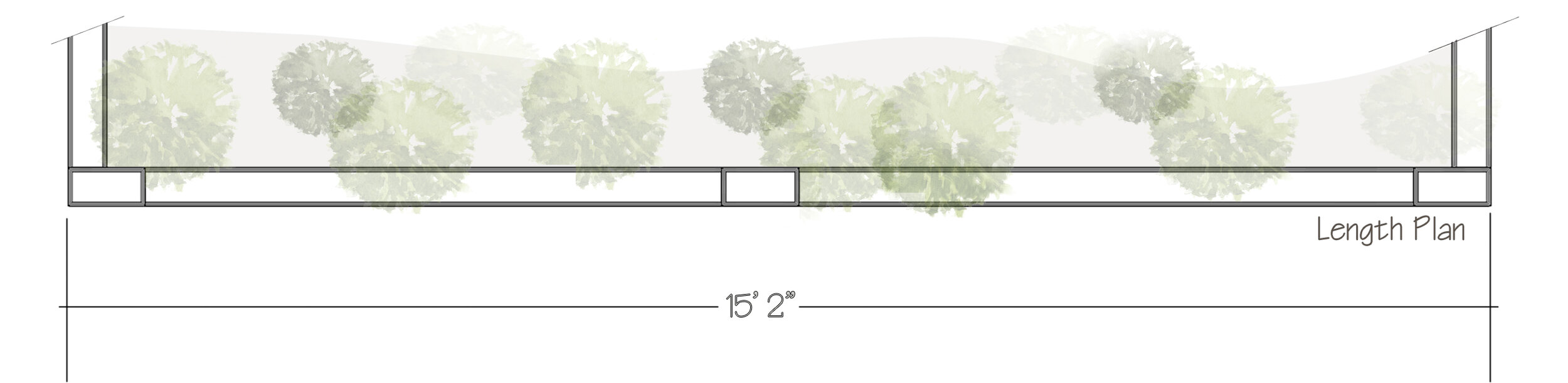

Decide on the size that you want for you beds. The BTL bunk beds are 4 feet wide and by 15 feet long. Size can vary depending on preference and space available. It’s also important to keep in mind dimensions of the local materials you will use so you can limit waste when cutting. Dig and pour a concrete footer that outlines the footprint of the bed. The footer should be slightly longer and slightly wider than the final outside dimensions of the finished table. The footer should be poured so that it produces a level surface to make the blocks easier to lay. From the footer you begin laying runs of block to make the bottom bunk. We used Interlocking Compressed Earth Blocks for our tables. But concrete blocks work as well.

Continue up with layers of block enclosing the bottom bunk to a depth of approximately two feet. If your location is on a slope there will not be a uniform depth in the bottom bunk and that will not be a problem. Just ensure that at the shallowest part of the bottom bunk there is at least 1 foot of depth. If the soil is too shallow in places it will inhibit the ability for plants to grow well in the bottom bunk.

After the bottom bunk is at an appropriate depth, at each corner and in the middle of the long lengths continue up with a column of blocks. These short columns will create legs for the drying tables. The legs should be approximately 1 foot high, enough space to create a good airflow underneath and be an appropriate level for workers to reach and turn the cherries. Soil, compost, and manures can be added to the enclosed area of the bottom bunk. The garden bed material depends on what you have available (coffee waste, soil, compost) and what you want to grow. Coffee nursery bed material is different from bedding used for growing vegetables. The top bunk is a porous metal table that rests on the six legs of the bottom bunk. We created a frame from metal hollow tubing and then applied 1 inch screen mesh to the frame. Sizes and types of materials for this frame could vary from place to place based on availability and on the size of the beds to be constructed. Attention should be given to use materials and sizes sufficient to create a rigid frame. The frame should not bend and deflect when loaded with wet coffee. If the frame or the wire used to cover it bends under load it will create low places on the table where the coffee will be deeper and will not dry as well. A rigid surface for the table allows the processer to create an even layer of coffee that will dry more uniformly.

Over this metal frame a layer of shade cloth or agricultural cloth is applied. Again, there is opportunity for variation with this material. Whatever material is used it should be resistant to UV decay, sufficiently closed to keep coffee from falling through any holes/openings, and sufficiently open to allow air to come through the material to dry the coffee from below. The mesh should not be fastened down because it is useful when compiling the coffee for night rest and for collection when dry. The final piece for the top bunk is a tarp that will cover the coffee at night and during rainy conditions to prevent rewetting of drying coffee. Plastic or any water repelling material can be used. The material should not be transparent. We were able to use a black parachute-type material that is both waterproof and tear-proof.